New problem points

Some of the main reasons for vehicle downtime and repairs are related to wiring harness. Despite technological advances, environmental stability remains an ongoing challenge. It’s worth mentioning that fully functional anti-lock braking systems (ABS) have been around since the 1970s. But most of these systems were forced out of the market due to cabling issues.

Decades later, the National Highway Traffic Safety Administration’s federal motor vehicle safety standards are finally mandating ABS

on commercial and passenger vehicles because the latest electrical systems finally meet the stringent requirements for such safety.

With the ever-increasing functionality of modern automobiles, which may have hundreds of wiring connection points, the integrity

of the electrical system becomes critical because any single point of failure could bring down the entire system. In the past, unsealed connectors and electronic control units (ECUs)

were common in vehicles, but now most of these components are sealed to prevent moisture intrusion.

As the design of these critical electrical system components has advanced, stresses caused primarily by temperature fluctuations and

water contamination have shifted potential failure points to the next weak link in the system: hinge points and ring terminals.

These parts have long been a concern for corrosion issues, but recent practical experience has shown that as the entire electrical system evolves,

they have become the primary focus of improvement and are driving all major car manufacturers to update their electrical standards.

Give two examples:

The first is the ground connector located on the outside of the chassis harness, which is exposed to moisture. A sealed ECU connected to it is securely installed in the vehicle cab.

However, due to temperature changes, the amount of air in the ECU will produce pressure changes,

thereby sucking salty moisture into the ECU, causing failure.

This “siphon” phenomenon has now been recognized throughout the automotive industry,

with some OEMs even jokingly calling sealed ECUs “lung boxes”.

In another case, a supposedly sealed joint was exposed to water splash in the engine bay.

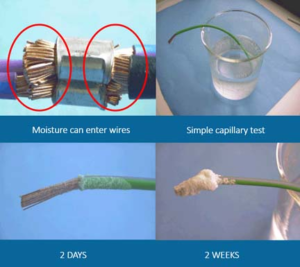

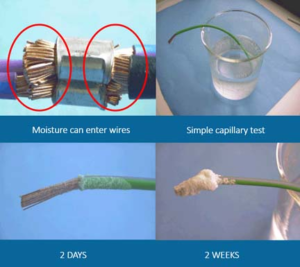

Due to the capillary action between the copper strands, water continued to enter the entire harness,

and eventually the entire harness had to be replaced. This powerful capillary action can be easily reproduced in the laboratory using saline (see Figure 1).

room for improvement

For years, the wire harness industry has relied solely on adhesive-lined heat shrink tubing to seal connectors and protect eyelet terminals, but with new OEM testing standards in place, wire harness manufacturers are being forced to verify connectors are sealed, exposing problems .

Wire harness engineers may mistakenly believe that if the heat shrink tubing hot melt glue flows, the joint will definitely be sealed, but this is not always the case. Although heat shrink tubing is very reliable when applied correctly, in many cases the application process is unproven.

Heat shrink is also limited due to the complexity of the hinges and the geometry of the terminals that cannot be sealed with heat shrink adhesive alone.

This is especially true as the number of wires terminated to a single splice or ring terminal (the kind with a hole) increases.

This forced the industry to start looking for and testing alternative solutions for wire sealing, such as adhesives and butyl rubber, but these solutions proved to have their own problems, including inconsistent and labor-intensive manual application, compatibility of wire insulation problems and environmental degradation.

a new approach

That’s when a low-viscosity liquid sealant was developed that solved these problems by sealing wires in a whole new way. This is a low viscosity liquid sealant that uses capillary forces to wick between strands and cures quickly to form a durable, semi-flexible barrier that provides a permanently effective sealed joint or terminal for the entire life of the harness.

It features a unique automotive-grade formula that provides excellent flex properties over a wide temperature range and is extremely resistant to moisture and chemicals. Once the sealant is in place, water and contaminants are permanently blocked and can no longer wick, preventing most corrosion failures.

Because the advanced sealing method works at the strand level, it can provide a seal on most splices, even with heavy wires and substandard construction (lined with heat shrink tubing and butyl rubber may not seal). This allows future wire harness designs to successfully combine more leads into fewer connectors.

Sealant can be applied to the terminals using precision dispensing or by immersing the entire joint in a bath. The method will depend on the joint structure and the processes required for fabrication.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!